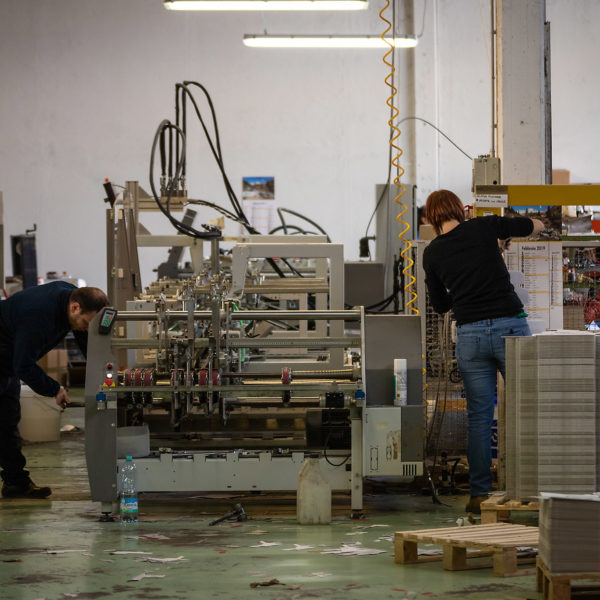

Bobst Expertfold 110

The last manufacturing process consists in turning a die-cut board in to a folded-glue blank.

When the die-cut blank passes through the folder-gluer, a selection of specially positioned guides, rotary hooks and other devices fold its panel to their required position, while adhesive system applies up to 8 glue points to appropriate location. Then the blank will be placed under pressure for glue to cure.

To each tips of the folder-gluer there is an operator. One takes care of positioning die-cut blanks on the equipment at beginning of the process, the other at the end of the process arranges the folded and glued blank to be delivered.